Metal injection molding of titanium and titanium alloys

01 Introduction

Titanium and titanium alloys account for almost half of density of iron. They have low density, good corrosion resistance, high specific strength and satisfactory biocompatibility. They are widely used in aviation, aerospace, chemical industry, biomedicine and other fields, and bring huge economic benefits to human society, especially in replacing invalid bones such as dentures, roots and prostheses with human implants. Titanium and titanium alloys are good material that can benefit mankind.

However, the most difficult problem in powder llurgy is how to reduce or avoid the occurrence of oxidation of titanium and titanium alloys. According to the observation of the standard free energy-temperature diagram of oxides drawn by Gibbs Free Energy, the cost of reducing oxidized titanium or titanium alloys back to l is enormous, which is not in line with the economic benefits. This is the reason that titanium and titanium are combined in powder also. The disadvantage of llurgical process, compared with iron family materials, lost the advantage of processing cost. It is no wonder that the advantages of titanium and titanium alloys in traditional bulk processing are much higher than those of powder llurgy, which is the first thing that powder llurgy practitioners should know.

02 Points for Attention

In order to succeed in powder injection molding of titanium and titanium alloys, the following methods must be adopted:

• If we hope control the oxygen content of the initial powder, the oxygen content of the powder must be controlled below 3000 ppm, preferably less than 1000 ppm, and only when the powder with low oxygen content is purchased can the good product be produced.

• In the process of degreasing, attention must be paid to the opportunity of reaction with oxygen. Mixture powder and binder must be carried out in a protective atmosphere, injection molding must minimize the reduction of heating and holding time, degreasing process should be protected by reducing gas or replaced by reducing oxalic acid degreasing, and sintering in vacuum or protective atmosphere immediately after degreasing.

• The design of sintered bearing plate and support system uses zirconia plate and small sponge titanium sacrificial arrangement which are not easy to be preempted by titanium to help reduce the oxygen content in sintering system.

• The addition of oxygen-rushing components, such as magnesium, in the material powder system may lead to variations in the composition of titanium and titanium alloys, and worse strength of titanium and titanium alloys after sintering.

2.1 Selection of Powder

The use of powders with low oxygen content is the preferred choice for injection molding of titanium and titanium alloys, which means that the powders are spherical powders by aerosol method, which are cooled under pressure by inert gas. The powders are large and round with low oxygen content. At present, the main powders are Carpenter in the United States and Sandvik in the United Kingdom. The particle size of powders is suitable for d50=10~12um, which is too small. Powder is easy to oxidize and the process is dangerous; water atomization method is too small and rough, and the particle size of mechanical crushing method is too large to be suitable for injection molding process; another theory supports the use of titanium hydride (HTi) powder to remove hydrogen and to crush round powder with high energy such as plasma treatment. Although the cost of obtaining raw materials is very low, patent disputes and investment in control equipment are quite high, which is not yet universal.

2.2 Binder formula

Titanium and titanium alloys have two feedstock systems. It is suggested that the formula is better than that in the range of Shrinkage from 1.166 to 1.220 as shown in Table 1 below. These formulations are already on the market.

Binder formulation of Titanium and Titanium Alloys

OSF = Oversize Shrinkage Factor

Due to the oxidation of titanium and titanium alloys, it is suggested that the volume of l in the formulation ratio should not exceed 63%, so as to avoid the possibility of friction between powder in injection molding and feedstock mixing. Once the friction temperature is too high, the possibility of oxidation will increase.

2.3 Notices for feedstock preparation

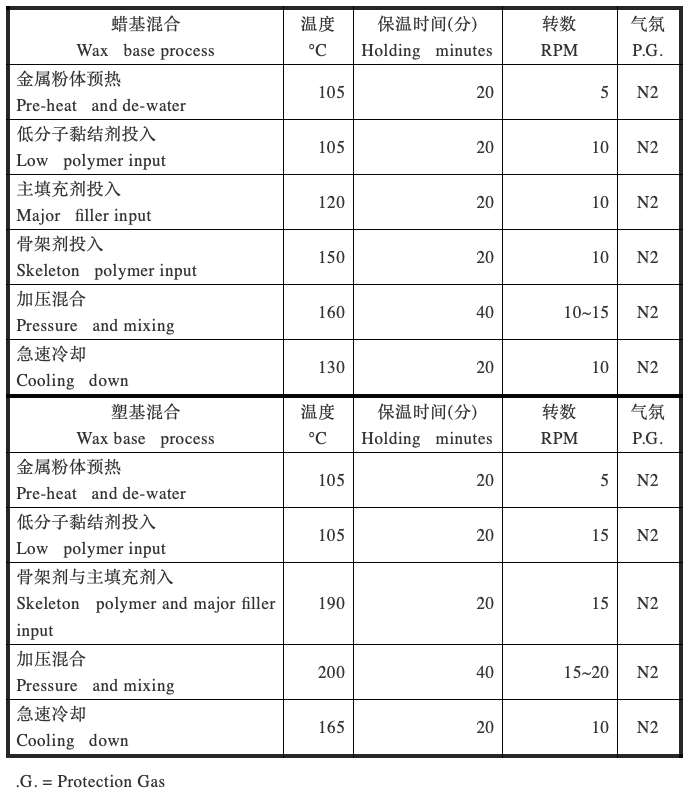

Particular attention should be paid to the control of the order of feedstock materials and the temperature of mixed feedstock, as described in Table 2. The mixing procedure of the two kinds of feedstock is suggested. It is noticed that the mixing process must be carried out in order to protect the atmosphere for oxygen removal. It is also noted that all macromolecule binder particles or powders must be dried to ensure that there is no moisture, wax and stearic acid, which are difficult to dry, are low molecular binders. It is suggested that water be removed by low temperature vacuum.

Suggestions on feedstock mixing procedure

03 Major process

Once the feedstock is completed until injection molding, it is the safest state of the whole powder, which can be exposed to air, but during the heating of the injection process, care must be taken not to let the feedstock stay in the barrel for too long. Once the injection process of plastic- d feedstock fails and adjusts the machine, it is necessary to set the temperature of the nozzle and the maximum temperature area in 10 minutes and cut off the temperature if not working, so that the feeding temperature is lower than 150℃.

Titanium and titanium alloy billets after injection molding are no different from those of common l materials and can be placed in air. Titanium and titanium alloy powder coated with binder can effectively block oxygen in the air. After degreasing, whether solvent degreasing or reductive oxalic acid degreasing (strongly oxidized nitric acid degreasing is not recommended), first of all, to ensure that the temperature leaving the furnace should be below 50℃. Celsius to ensure that oxidation does not occur, the degreased Brown billet is porous, very easy to react with oxygen in the air, please note. The shorter the time of placing the brown billet outside, the better, it will enter the sintering system as soon as possible.

The design of sintered supporting plate and sintering box is very important. Because titanium and titanium alloys have high oxygen affinity, they can even capture oxygen in alumina (Al2O3) at high temperature. Therefore, zirconia plate (ZrO2) is recommended for ceramic bearing plate, but the material of carbonization or nitriding should not be chosen. Titanium and titanium alloys also like affinity for carbon and nitrogen elements. In the past sintering experience, the placement of titanium sponge in the sintering box as a sacrificial block of oxygen grabbing is effective but reduces the efficiency of the sintering furnace. It consumes a lot of titanium sponge at a time, occupying space and consuming heat are negative.

The above experience is shared in the production of titanium and titanium alloy powder injection molding. Operators must be cautious. The state of pure titanium powder is high risk. These non-ferrous ls (density < 4.5g/c.c.) all have the risk of dust explosion, although titanium and titanium alloys are the least active non-ferrous ls.